Manufacturing data and AI services: cut maintenance 25% with zero downtime

Downtime and low visibility drain your profits. We build manufacturing intelligence to help you solve that—without stopping your operations or demanding months of your time.

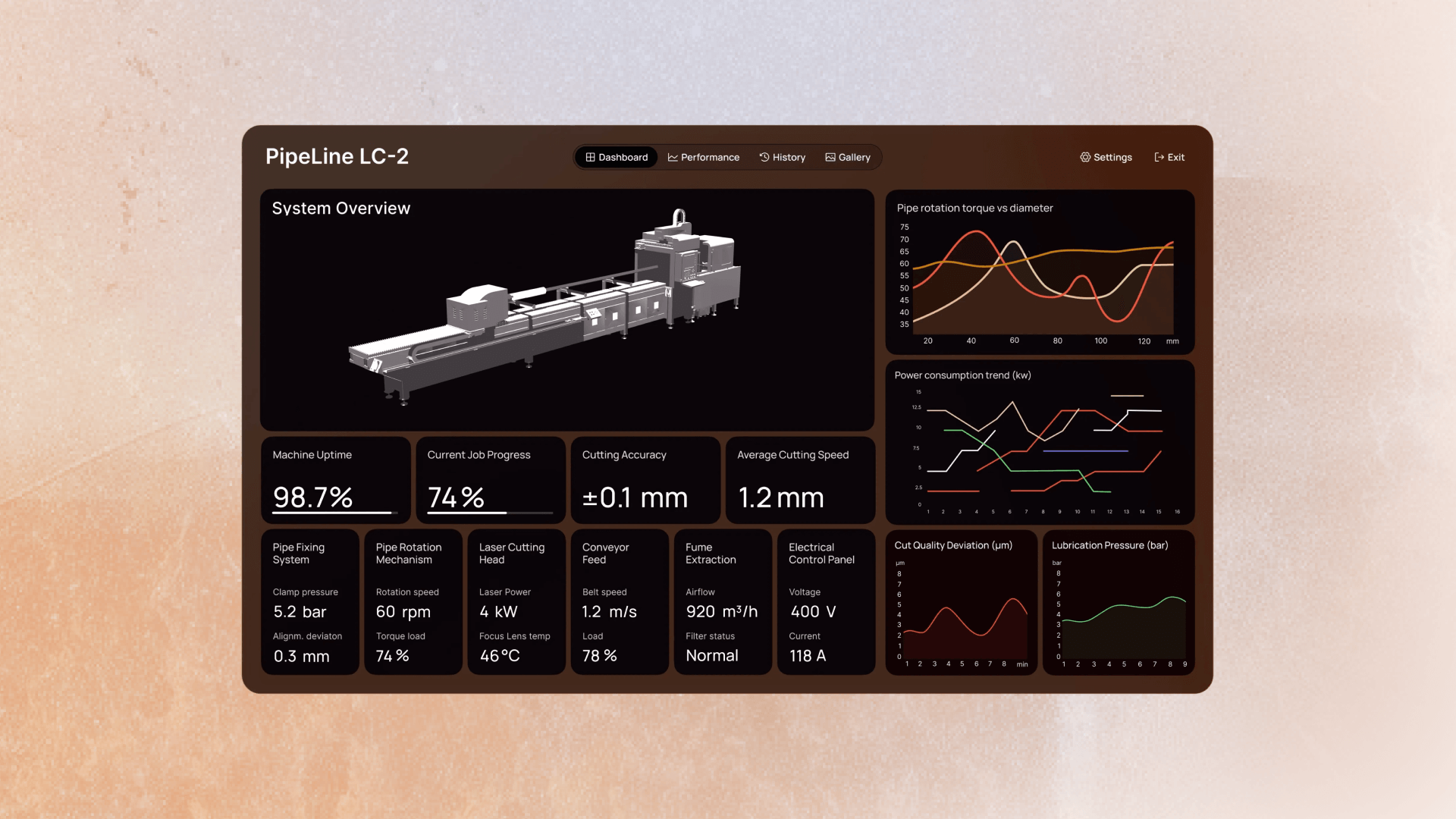

- Digital twinning

- Predictive maintenance

- Real-time monitoring & alerts

Trusted by 200+ enterprises globally

AI and data solutions we deliver

Already deployed by companies like Bosch and Norsk Hydro

Solving chronic manufacturing problems

Turn factory data into secure, real-time intelligence your people can actually use to fix inefficiencies and lift productivity—measured in dollars saved and hours recovered.

- Cut defects and waste

- Stop unplanned downtime

- Predict disruptions before they show

Success stories from our clients

Don't take our word for it...

“Hiflylabs displayed a profound understanding of the latest AI tools. They have been more than just technical wizards, but patient mentors and collaborative partners.”

Benedek Koncz

-Division Manager of Digital Technologies and Engineering, Semilab

In-house experts in manufacturing

Mihály Darányi

Director of AI & Data Solutions and Head of Advisory team with deep domain expertise across manufacturing, energy, telco, and retail. Leads AI strategies and initiatives for enterprise US and EU clients. Specializes in AI governance, ROI-driving adoption, and GenAI product management.

András Korompai

Senior Project Manager and Databricks DPS Project Delivery lead (DACH) with a proven track record in manufacturing intelligence and automation. Drives practical AI and data initiatives that help tier-1 manufacturers solve chronic operational problems like unplanned downtime and resource waste.

FOR BUSY LEADERS WHO CHAMPION INNOVATION WITHOUT BREAKING THINGS

Stop reacting to problems. Start preventing them.

Every unplanned shutdown that cuts your revenue. Every supply chain issue that erodes your margins. Every productivity gap that costs you your people. Can be solved with the right data and tools at hand.

Why brands like Bosch trust Hifly

Advisory and E2E service

We give you your time back by finding and solving your most expensive operational problem. Hifly owns the entire process—advisory, engineering, integration, and adoption. You stay in control, receive reports, and get involved as much as you want. No overhead, no pressure on your throughput.

Built to fit, not to break

We don't rip out your ERP, replace your MES, or force digital transformation. We build intelligence on top of your data and infrastructure and make it usable for the people who need it—line managers, repair teams, plant operators. Your workflows keep running, only faster, safer, and more productive.

70% AI-to-production rate

Hiflylabs boasts a 70% AI-to-production rate, higher than the market average. Why? Because we design and build practical solutions for real environments, not labs. At speed—with field-tested methodology, reusable blueprints, and partnerships with top AI, data, and cloud platforms.

Adoption and safety

Change management is built into our process. We train your teams, address resistance, and implement guardrails and access controls within your security framework and requirements. So you can finally use your data, and your people become more productive with technology instead of being replaced by it.